|

| February 12, 2013 | Volume 09 Issue 06 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Researchers use liquid metal to create super-stretchable wires

By Matt Shipman, NCSU

Researchers from North Carolina State University have created conductive wires that can be stretched up to eight times their original length while still functioning. The wires can be used for everything from headphones to phone chargers, and hold potential for use in electronic textiles.

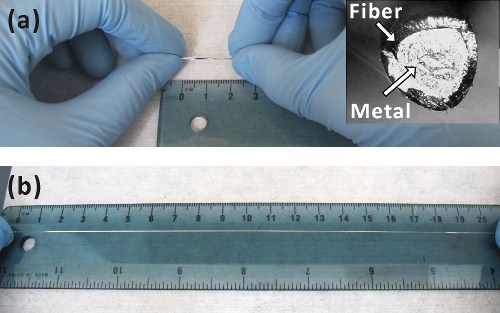

This tube, filled with liquid metal, can be stretched many times its original length.

To make the wires, researchers start with a thin tube made of an extremely elastic polymer and then fill the tube with a liquid metal alloy of gallium and indium, which is an efficient conductor of electricity.

"Previous efforts to create stretchable wires focus on embedding metals or other electrical conductors in elastic polymers, but that creates a trade-off," says Dr. Michael Dickey, an assistant professor of chemical and biomolecular engineering at NC State and co-author of a paper on the research.

"Increasing the amount of metal improves the conductivity of the composite, but diminishes its elasticity," Dickey says. "Our approach keeps the materials separate, so you have maximum conductivity without impairing elasticity. In short, our wires are orders of magnitude more stretchable than the most conductive wires, and at least an order of magnitude more conductive than the most stretchable wires currently in the literature."

While the manufacturing of the new wires is relatively straightforward, Dickey notes that one challenge needs to be addressed before the wires can be considered for popular products: how to minimize leakage of the metal if the wires are severed.

The paper, "Ultrastretchable Fibers with Metallic Conductivity Using a Liquid Metal Alloy Core," is published online in Advanced Functional Materials. The paper was co-authored by Shu Zhu, a former undergraduate at NC State; Dr. Ju-Hee So, a former Ph.D. student at NC State; Robin Mays and William Barnes, Ph.D. students at NC State; Dr. Sharvil Desai, a former postdoctoral researcher at NC State; and Dr. Behnam Pourdeyhimi, the William A. Klopman Distinguished Chaired Professor of Materials in NC State's College of Textiles and a professor of chemical and biomolecular engineering in the university's College of Engineering.

The research was funded by a National Science Foundation (NSF) CAREER award and the NSF's Research Triangle Materials Research Science & Engineering Center.

Published February 2013

Rate this article

View our terms of use and privacy policy